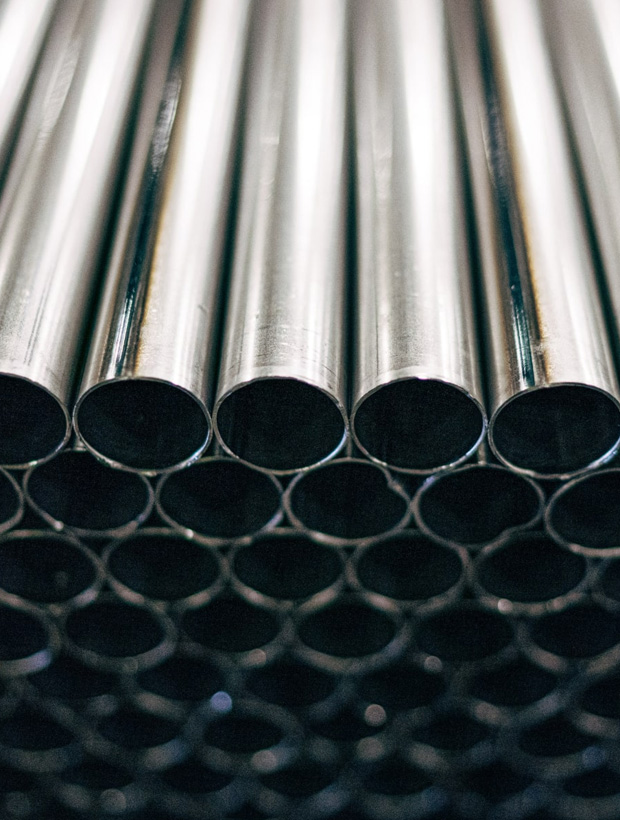

Tubular components are structural or functional parts made from metal tubes, commonly manufactured using Mild Steel (MS), Stainless Steel (SS), Aluminum, or other alloys. These components are widely used in various industries, including automotive, construction, infrastructure, furniture, and industrial machinery. They are typically produced through cutting, bending, welding, and machining processes to achieve the required design and functionality.

- High Strength & Durability – Tubular components provide excellent load-bearing capacity and long-term reliability.

- Corrosion Resistance – Available in coated or stainless steel versions to enhance resistance to rust and environmental damage.

- Lightweight yet Sturdy – Tubular structures offer a balance between weight reduction and mechanical strength.

- Customizable Shapes & Sizes – Manufactured in round, square, rectangular, or elliptical profiles as per design requirements.

- Cost-Effective & Easy Fabrication – MS tubular components are affordable and easy to process, making them ideal for mass production.

- Versatile Applications – Used in automotive chassis, furniture frames, piping systems, scaffolding, handrails, and structural supports.

- Good Weldability & Formability – Mild Steel and Stainless Steel tubes can be easily welded, bent, or machined for various applications.

- Aesthetic Appeal – Suitable for decorative and architectural applications due to smooth surface finishing options.